The “Tiny” Gym That Does Big Things

The Boulders Climbing Gym is a not-for-profit climbing facility in a small town near Victoria, BC which lies on the western edge of Canada. The all volunteer facility has a mandate for making climbing accessible for everyone, regardless of physical ability or ability to pay.

Over the years, the gym has gone through several changes and expansions and with over 13,000 square feet (1,208 square meters) of climbing space, the gym has become not only a community facility, but a unique social enterprise, providing adaptive recreation and rehabilitation programs, youth recreational and competitive programs, as well as facilitating a climbing academy.

adrex.com takes us inside to see what the little gym has become.

“It all started with Stellys Secondary School’ teacher who liked to climb, and saw climbing as a valuable teaching tool. In 1995, Peter Mason took his enthusiasm and some perseverance, and built a small climbing wall on the outside of the school gym. Twenty years later, the Boulders is now home to a high school academy, youth teams, climbing groups and of course regular folks.

“Our competition facility (costing about $3m, raised through grants and donations) opened in late 2011. It includes a certified 15m speed wall (a new women’s world record was set on it in May 2015 at the kick-off to the IFSC Speed World Cup series), and is over 18 meters tall. It is indoor/outdoor thanks to a large 15.5m by 15.5m “door” that opens and closes,” Kimanda describes the gym’s most recent expansion.”

The Boulders is a one of a kind facility in North America and arguably the premier training ground for Canadian and even US athletes looking to gain an advantage on the comp circuit. The facility also has hosted the IFSC Youth World Championships in 2013 as well as World Cup training camps attended by the like of Adam Ondra and others.

Find more great photos and info at Adrex.com.

Flathold Enters the US Market

Flathold, the Swiss maker of climbing holds and volumes announced their entry into the American market last week.

From the Flathold Facebook page:

“After a couple years of development we are proud to announce that Flathold is officially available in North America! We are happy to announce our partnership with Chris Danielson, our good friend and distributor of Flathold with his company Thread Climbing. He has everything ready and we invite you to check out the new website that has a specific “North America” section! A new catalog is also available to download. Flathold is being produced in almost the full range, and we have re-built some sets for better combination of shapes and good pricing. We hope to bring some excitement to routesetters…”

Founded by the international routesetting Chief Manu Hassler, the Flathold line features a mix of smooth lines and natural shapes that are quite different from what’s currently available in the US market. However, in North America the volume market is dominated by geometric wood volumes and fiberglass volumes have had trouble gaining a toe hold. This could have to do with the higher cost of fiberglass volumes and the lack of consistent and quality texture. With the Swiss precision that Flathold is known for we’ll see if they can get over some of those long-standing hurdles.

All the Flatholds are shaped by Hassler and his partner Mathieu Achermann. Chris Danielson, who handles sales in the USA, Canada and Mexico, tells CBJ that the holds available in North America will all be produced in Colorado. He also adds, “These guys approach climbing holds, and their business overall, with a certain Swiss refinement and perfectionism that I greatly respect.”

N. American buyers will have a slightly modified line up available. “The costs to begin top quality production are quite high,” Danielson said. “So we made a couple choices to simplify things and keep it more cost-effective for customers as well.” The whole team at Flathold also wanted to bring the best to the US market. “We wanted to select the sets for initial production that we personally thought were only the absolute best shapes, and we believed customers in North America would be most interested in,” Danielson said.

From the Flathold website:

[For Manu] to carry his holds from one competition to another, he needed a mix that was lighter and stronger. The idea was to create a different type of holds, among which there could be more “flat” holds. This is when the name and Flathold as a brand began to take shape. Manu draws a lot of his inspiration from his work as a route setter. The goal being to create shapes that inspire more and more specific movement. With Manu, there is this idea of movement perfected by the hold. What results, among other things is a certain purity, a particular scarcity of excess. Manu is a little like his holds; edgy or fleeting with no deception. “To push route setting”, in his own words, means to develop techniques, shapes, textures, a material; contribute as much as possible to the evolution of the discipline.

In the last year Flathold has become extremely popular with the US crowd. Their volumes have been seen at the 2015 Bouldering Open National Championships and this year’s Vail World Cup, as well as across Europe for the last several years. And even though their volumes garner the most attention they also have a full line of bolt-on and screw-on urethane holds that will soon be making their appearance in a climbing gym near you.

Bridge Climb Opens in Oregon

Climbers in central Oregon have a new place outdoor crag: a 70 foot tall bridge with three 210 foot arch spans. The Maple Avenue Bridge, located in Redmond, Oregon received it’s first routes in July 2015, and had an official ribbon cutting on August 26th.

The brainchild of local climber Ian Caldwell, the climbing project will be entirely community funded. Caldwell hopes to construct one demonstration route by this fall, eventually posting eight routes on the different arches of the bridge. The routes will be made up of artificial climbing holds bolted into the concrete of the bridge.

“This kind of bridge is unique in that it’s over a park,” said Caldwell, who added that the wall would be one of the few overhang routes on a man-made structure in the country. “There’s other bridges like this, but they’re over railroad tracks or 600-foot gorges.”

For more info visit www.climbmaplebridge.com

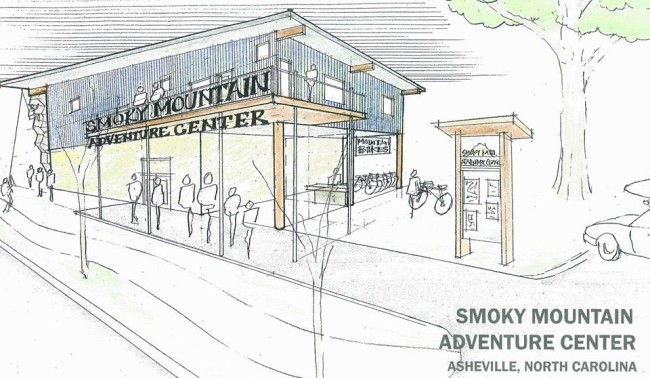

Asheville Gym Expansion Soon to Open

First opened in 1993, Climbmax of Asheville, North Carolina will be expanding from their original downtown location and teaming up with Smoky Mountain Adventure Center in the hip River Arts District. The Citizen-Times recently had the chance to get a behind the scenes look at the new facility.

In addition to a 42-foot-high outdoor wall, the north, south and west walls of the 34-foot-high indoor wall will be completely climbable around the inside perimeter of the building. There will be an upstairs yoga room, Earthsports Design, a workout room, and a bar called the Asheville Hangout, which will sell root beer, as well as local cider and draft beer that people can enjoy on the wrap-around deck overlooking Amboy Room and the French Broad River Greenway. Downstairs will be a coffee bar selling smoothies, coffee and tea.

“We had some challenges with lending and with permitting. We had to wait for a variance to sit closer to the street. We didn’t want to disturb the cliff line,” Stuart Cowles, Founder of the adventure center said. “Also, we were trying to save the trees on the property, and we’re being proactive at being flood proof in a very challenging site. All of that has set us back.”

According to the Citizen-Times article, the center began with a $100,000 grant from the Buncombe County Tourism Development Authority in 2010. Cowles and part-time Asheville resident Daniel Nash bought the land, which they will lease to Smoky Mountain Adventure Center, which in turn will lease to Climbmax, Earthsports and two companies that will provide tube, raft, kayak, stand-up paddle board and comfort bike and kids mountain bike rentals.

Bringing Tech Savvy to Climbing Shoes

For $350 you too can have a pair of custom climbing shoes made by a 25 year old MIT graduate, and they just might be the most comfortable shoes you’ll ever climb in. At least that’s what Laura Shumaker has been working towards with her company SFT Climbing.

The aptly named Shumaker is the Founder and Lead Designer for SFT Climbing, a custom shoe manufacturer based Sebastopol, California. By combining time honed craftsmanship with Silicon Valley tech savvy, Shumaker is attempting to bring a hybrid-designed climbing shoe to market. In the future she may end up disrupting the old guard of shoe design, but for now Shumaker just wants to make a quality product.

How To Become a Cobbler

After graduating from MIT with a Mechanical Engineering degree with an emphasis on product design, Shumaker took a job as a design consultant but knew she wanted more freedom to explore the products that she was interested in.

“I’ve always wanted to develop my own products,” Shumaker told CBJ in a phone interview. “To have that kind of freedom to take something I really care about, and make it a reality.”

Being mostly a boulderer, Shumaker knew about the discomfort of wearing cramped climbing shoes for a whole session and she told us, “that just seemed kinda stupid.” She said about the current climbing shoe design, “I’m not saying the state of the art is stupid, but that was the state of the art 5 to 10 years ago.”

And she is mostly right. There has not been much innovation in the climbing shoe market. Materials have been added like synthetic uppers but the rubber of today is eerily similar to the rubber of 20 years ago. Though the fit of climbing shoes went through a brief change when La Sportiva introduced the Slingshot rand and the Powerhinge to their high-end Solution climbing shoe, fit design seems to be in stasis.

“As shoe manufacturers, we’re all very lucky in that climbers are willing to put themselves through a lot of pain,” Shumaker said. “But we’ve reached a point where we don’t have to do that anymore.” By that she means there are technological advances that could be used to better advantage if manufacturers were willing to look for them.

That’s where the idea for an adjustable climbing shoe popped into her head, “A shoe that can go from downturned to relaxed and back,” she said. To do this, or to make any kind of shoe, the craftsperson first needs to build a “last” which the shoe is then built around. Shumaker designed a CAD model of her adjustable last and started the long process of learning how biomechanics effect the shoe design.

After a few prototypes the small SFT team quickly learned that with the right customization and fit a climber’s comfort level goes way up even without on-the-fly adjustment. “90% of the discomfort we were trying to address by adjusting our shoes just went away when you had shoes that were properly fitted,” Shumaker said.

SFT has completed 50 prototypes and recently finished their beta testing. Even though the adjustment system still needs more design work, Shumaker feels they have finally arrived at a point where it’s possible to take her last and unique digital manufacturing system to the public. “We’ve gotten really good feedback on the custom shoe so we decided to make that our first product,” Shumaker said.

Funding

Shumaker, like any good entrepreneur, knew she needed funding if her shoes were ever going to see the light of day. That’s where Upstart, an online lending platform run by former Google data scientists, came into the picture.

In 2012 when Shumaker conceived of SFT, Upstart operated a bit differently than it does now. Entrepreneurs would go in front of a group of potential investors and pitch either their idea and ask for seed funding. The investors wouldn’t so much invest in the product or company, per se, but rather the person behind the company. If the investors like the idea or found the person worthy they would invest a sum of money in exchange for a percentage of the entrepreneur’s future income, regardless of where the income came from.

With Shumaker’s education and experience she was a sure bet for investors and easily picked up the necessary cash to get SFT off the ground.

Business Insider profiled Upstart in June 2015.

Upstart was founded in 2012 with the idea of connecting young entrepreneurs with investors. But last year, it pivoted to the current online-lending platform after realizing its future-looking analytics would be better used in the personal-loan market.“What [Upstart] has done here is identifying ‘future prime borrowers,’” Girouard told Business Insider. “Our modeling is really focused on not what you did in the past, but what’s likely to happen to you in the future. These are people that are going to be doing great things, earning a lot of money, becoming wealth creators over time.”

The Process

SFT shoes fall in the middle of the climbing shoe distribution model. You cannot buy them off the shelf like most climbing shoes. But they aren’t quite 100% custom-made in the traditional way, which involves a customer going into the shop and having their feet cast so a craftsperson can hand-make a pair of shoes that fits the buyer’s feet exactly. This custom process can take up to a month to complete and costs over $500 a pair.

SFT’s manufacturing process combines the ease of the Internet, some old school paper and some standard manufacturing technology to create a streamlined custom manufacturing process. This allows the customer to order a pair of shoes from the comfort of their home laptop and receive them by mail two weeks later.

The process begins with a customer tracing the outlines of their feet on an 8.5 x 11 sheet of white paper and scanning or taking a picture of the outline. Next, the customer takes two photos of the sides of their feet and sends all that over to the SFT team.

SFT converts the pictures into measurements for the customer’s foot (based on the size of the paper) and feeds that information into a software program that scales and transforms the data into a 3D model. Those measurements are then put into the CAD model where the suede and rubber are scaled, laser cut and then hand assembled.

This process results in a climbing shoe that is built around the contours of an individual’s foot and has the performance enhancing benefits of a custom shoe, without the cost and time of getting custom shoes made in the traditional way.

The process isn’t perfect for all climbers, particularly people that need shoes with specific support for medical conditions or for people with unusual feet. Even though SFT gets the exact measurements of the feet to be shod, the software makes certain assumptions about the customer’s foot. “It assumes your feet look like feet,” she said. “For example if you’re missing toes my last won’t adapt to that. It would leave space at the end of your shoe where your toes are missing.” Shumaker says these customers should seek out a traditional craftsperson to make their shoes.

Mass Customization

Shumaker has no plans to compete directly with the big players like Five Ten and La Sportiva, which mass produce their shoes for a broad market audience. She instead likes to think of SFT as providing “mass customization”. For climbers who have reasonably normal feet but are sick of the lack of proper fit and comfort, Shumaker said, “I’m there for those people.”

SFT, which informally stands for “So Fucking Tight”, or “if you’re talking to your Grandma, Shoes For Technique,” Shumaker joked, is just beginning to get into the highly competitive climbing shoe market. Shumaker says she will continue to innovate and bring in new techniques that create efficiencies and cut waste.

“Our first goal is to completely digitize every step of the manufacturing chain,” she said. “And then to look at the steps again and say, where can we combine one… or maybe 3D printing can do multiple materials much more efficiently.” Though she cautions, “It’s been this long held promise that you could 3D print a pair of shoes, but from an engineering and biomechanics perspective…it’s not very functional.”

The SFT team is very small, with Shumaker doing most of the heavy lifting including R & D, design, assembly and company operations. But Shumaker wouldn’t have it any other way. “I’ve fallen in love with the process of boot-strapping a company. I like how it helps me think about the company’s priorities…about what kind of R & D to invest in,” she said. “I feel like I’m learning a lot more as a business person than if I had taken a load of investing in the first round. I’m really happy with what we’ve been able to do with the minimal funding we have.”

Walltopia Brings in Investors

Bulgaria-based Walltopia recently announced a partnership with two investments firms which will take a minority stake in the company. The first is BlackPeak Capital, a private equity fund investing in small to medium companies in Bulgaria with leading positions on global and domestic markets. BlackPeak which is funded by the European Investment Fund focuses its efforts on established companies with annual revenues between 1 – 30 million Euros. BlackPeak is a Co-Investor fund and requires a second investor on pari passu terms.

That’s where China-CEE comes into the picture. The China Central and Eastern Europe fund which was established by China Exim Bank is the co-investor on the Walltopia deal. According to the there website the CEE typically invests between $20 and $70 million in equity though all “transaction structures are always flexible and tailored to the needs of the business.” This is the first investment of the China-CEE Fund in Bulgaria.

“We are happy to welcome partners who share our passion for the product and who can drive value beyond money” said Ivaylo Penchev, CEO of Walltopia.

The partnership between Walltopia, BlackPeak Capital and the China–CEE Fund aims to support the company’s impressive growth and innovative amusement products. In 2012, Walltopia has expanded its portfolio of products and services towards the larger amusement and active entertainment market. The investment will also increase capacity and support the global roll-out of Funtopia, an amusement concept for indoor climbing for kids, which has already been launched successfully in Bulgaria, the U.S., Canada, and Israel.

Climbing is Popular in Boston! Duh

“If there isn’t an indoor climbing wall in your town, take a deep breath. By the time you exhale there is a good chance a new gym will be opening up right around the corner.” That’s what Wicked Local – Maynard had to say in a recent article highlighting the growth of climbing gyms in the Boston metro area.

“Climbing has grown exponentially,” said Pat Enright, owner of MetroRock Climbing Center. “I have been climbing for 25 years and when I first started there was probably only about 40-50 gyms in the entire country, and a lot of them were kind of small. When we first opened in 2004 that number had doubled.” Since then, Enright has opened two more gyms and plan on opening a third. Nationwide, there are more than 400 rock gyms. Enright, who opened the first MetroRock gym in Everett in 2004, has played a key role in the sport’s popularity locally.

The Maynard article is just one of many write ups, not only on the popularity of the sport, but also on the feasibility of selling climbing to the masses.

Another chain of gyms, Central Rock Gym, is expanding at an even faster rate. Their first gym opened in Worcester in 2010, and has since added locations in Hadley, Cambridge, Watertown, Randolph and Glastonbury, Connecticut.

“We are adding about one gym a year, climbing is certainly one of the fastest growing sports in America,” said Kevin Pickren, general manager of Central Rock’s Watertown location.