Top 6 Cities to Open a Climbing Gym

Britain Sets National Standard for Gyms

- 15-18m wide by 15-20m (49ft – 65ft) high, with a minimum 8m overhang, ideally extending to a 10-12m (32ft – 39ft) overhang in sections.

- Large flat panel construction to allow use of moveable volumes and features to give flexibility and creative options for routesetters.

- A standout design with spectacular competition features, but simple and easy to view at the same time (e.g.no hidden arêtes or edges).

- Not to include corners or grooves (which would give bridging rests).

- Separate isolation area with a warm-up wall.

- Competition wall capacity to hold at least 300 people (competitors, volunteers and spectators).

- Capable of having 10-12 competition style routes (i.e. wandering) set at any one time with at least 6 being able to run at once completely independently.

Awesome Walls

The NPC designation appears to be a win for both the BMC and the climbing facilities that are certified under the new standard. The first gym to receive the NPC designation, Awesome Walls in Sheffield, England, opened last month with a grand opening that included hosting the British Lead and Speed Championships. Awesome Walls Sheffield is the largest climbing gym in the UK, and having the NPC designation has added extra cache to the facility. “Having the title of NPC adds to our reputation of providing a quality facility that has met a national governing bodies criteria,” said Dave Douglas, Managing Director of Awesome Walls. “Even though the main competition wall will only be climbed by a very small minority of climbers, it is worth every penny as the WOW factor is just awesome when people see it for the first time (and repeatedly!). This wall will inspire a whole new generation of climbers to come and try harder and steeper challenges than they have ever dared climb before.”A British Invasion? Not anytime soon.

Currently the US does not have anything like the NPC. If a similar program was created in the US, new climbing facilities looking to meet the standards would have to continue the current trend toward bigger walls and more spacious venues. In the past 40 to 50ft walls were the norm, but in the past few years new gyms have been meeting the 49-65ft wall standard. Fitting 300 climbers and spectators into the building, however, is still a stretch for most new gyms. Bouldering walls are even further behind. The NPC standard requires almost a 100ft wide bouldering wall, which is a marked departure from the way US bouldering areas are currently being designed. Even if more international-level walls are built in the US, we still have a long way to building an international-level climbing team. As it stands now, Team USA does not have a dedicated training facility and the athletes do not have regular trainings together. Imagine, then, a time when competitive climbers in the US have a dedicated training center with routes set by professional routesetters from around the globe and elite-level coaches and trainers on staff. With the current financial state of the US federation this fantasy is unlikely to happen anytime soon. But it will come eventually, and when it does we will be well on our way to building world class climbing in America.ABS Routesetting Crew Wanted

ABS Open National Championship

The ABS Open National Championship will be held February 21 – 22, 2014 in downtown Colorado Springs at the Colorado Springs Auditorium. National Chief Jeremy Hardin will again lead the event and has four Assistant positions available for a week of setting some of the most creative bouldering problems seen in the U.S. ABS Open Nationals is the country’s premier bouldering competition featuring pro’s like Daniel Woods and Alex Puccio. 2013 ABS 14 National Championships – Men’s Highlights from USA Climbing on Vimeo.ABS Youth National Championship

The week following Open Nationals the ABS Youth National Championship (February 28 – March 2) will take place in the same location. National Chief Ian McIntosh will lead his first National crew through an intensive week of routesetting ending in a mind-boggling three day competition. There are three Assistant, two Apprentice, and three Internship positions available. This large crew allows for a great combination of up-and-coming setters wishing to make their mark on the national setting scene, while working under seasoned Level 4 routesetters. The three day competition is one of the most complicated competitions to orchestrate. Due to the size of the climbing wall the setters must go through a dizzying array of mid-comp turnovers which involve changing individual boulder problems to fit upcoming categories without the comp ever stopping. 2013 ABS 14 National Championships – Youth Highlights from USA Climbing on Vimeo.ABS Divisional Championships

Also available are coveted routesetter internships at two of the five ABS Divisional Championships. These two positions will be available at the Divisionals hosted by the BLOC bouldering gym in Tucson, Arizona and Gravity Vault in Upper Saddle River, New Jersey. Both of these Divisionals will be lead by USAC Level 5 Chiefs, and according to USAC Routesetting rules, the Chiefs can have an intern that is a Level 2 setter. But as the official announcement states, “There is NO certification outcome from working as an Intern at a Divisionals competition, but you will gain valuable experience with a Level 5 Chief Routesetter at a Championship level event.” Like all Divisional Championships, these comps will take place January 11 – 12, 2013.Apply

The deadline for all applications is November 15, 2013. Go to usacsetting.net for more information and to download an application.Cleaning Chemicals a Danger to Equipment

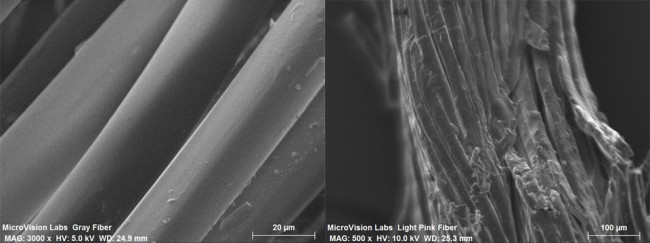

Yesterday I went top-roping at my local gym and as I was being lowered, I heard a pop. I looked down to see that my harness has ripped off in the waist. I felt myself falling backwards so immediately grabbed the rope and was lowered safely to the ground. I have kept the harness in pristine condition in my gym bag and it has never been abused or used outdoors.QC Labs asked the customer to send in the harness for evaluation. They determined that the harness had been chemically contaminated, and that the chemical had completely dissolved the nylon threads attaching the waistbelt webbing to the harness. Most frighteningly, while the nylon threads used to sew the harness together had been destroyed, the polyester webbing showed no signs of damage; only a very careful inspection of the equipment would have revealed its danger. Although neither the QC Labs or the customer could determine exactly how or to what chemical the harness had been exposed, QC Labs was able to narrow it down to some type of acid. Using off-the-shelf cleaning chemicals they performed some controlled experiments to see if they could recreate the failure and measure the effect of each chemical on a climbing harness.

- muriatic acid: 97% reduction in strength

- sulphuric acid (aquarium cleaner): 92% reduction

- clorox bleach: 73% reduction

Several years ago there was a rope incident and after analysis it ended up looking like the rope was somehow contaminated with acid. How the rope actually came in contact was never determined. So this is the second incident I’ve personally looked into regarding chemical contamination of climbing gear – and luckily in both cases no one was hurt. Also in both cases, the end result was that the customer doesn’t really know how this chemical contamination occurred. Scary.Black Diamond, in the product manual for their harness, advises that “Climbing gear must not come into contact with corrosive materials such as battery acid, battery fumes, solvents, chlorine bleach, antifreeze, isopropyl alcohol or gasoline.” While not common these days, muriatic acid is sometimes used to clean climbing holds. And certainly bleach and bleach-containing chemicals are used in many gyms for cleaning. It’s easy to imagine how the climbing equipment in a gym could be exposed to bleach that is used to clean floors or countertops, or to strong solvents used to clean climbing holds. This incident highlights the importance of properly storing these chemicals away from all climbing equipment, particularly all nylon product such as ropes, draws and harnesses, and to be cautious when using cleaning chemicals in areas where climbing equipment could come into contact with them. By exposing climbing equipment to these chemicals, either through a large spill or by repeated contact with small amounts, the equipment’s safety could become critically compromised without a visual warning that it has been damaged.

Read full QC Lab article here: The Electric Harness Acid Test