[Editor’s Note: This article (revised on August 7, 2023) provides a snapshot of recent sustainability efforts taking place in the holds sector of the industry and is not an exhaustive list. After additional fact-checking, an estimate of climbing hold disposal was removed from this article on July 12, 2024.]

Climbing grips have come a long way in recent decades, a history which Jackie Hueftle deftly details in the second and fourth issues of Route Setter magazine. As technology has evolved, holds have gone from being simple, dull, abrasive, fragile and heavy to being complex, colorful, comfortable, durable, lightweight, dual-tex and hollow-back. The industry has seen the introduction of fiberglass macros as a retail commodity, not to mention enormous wood volumes being ubiquitous in most gyms.

There are myriad variations and nuances here, but in its simplest form the production of a modern climbing hold consists of a few core steps: a shaper designs a new shape for a climbing hold brand using artist foam; a climbing hold manufacturer casts molds of the shape out of silicone which they pour liquid polyester (PE) or polyurethane (PU) into that hardens and is demolded; the new climbing holds are sanded, drilled, cleaned, shipped, and purchased by climbing gyms and routesetters around the globe.

As with any factory production process, there are always environmental impacts. Climbing holds and macros are most often made of plastic that’s not recycled and not recyclable, and so most old or broken plastic holds cannot be reprocessed or reused; foam, plastic, work supplies and finished grips need to be transported between the various producers and consumers, typically via gas-powered trucks or even airplanes that release tons of carbon dioxide into the atmosphere; and there are health concerns for personnel as well, who may wear heavy-duty masks during the shaping, casting and finishing stages of production to avoid breathing particulate debris and chemicals emitted into the air.

But concern for environmental issues has long been part of climbing culture, and that concern has led to countless sustainability efforts over the years, including in the holds sector. Lately, we’ve come across several efforts on the “Reduce-Reuse-Recycle” spectrum at climbing hold businesses in different parts of the world. Whether big or small, experiments to further reduce the environmental impacts of a climbing hold product’s life cycle are well underway.

Reducing Carbon Footprints

In business sustainability circles, a common way to understand environmental impact is the idea of a carbon footprint. According to scientists at the Stockholm Environmental Institute, a carbon footprint can be defined as a “measure of the exclusive total amount of emissions of carbon dioxide (CO2) that is directly and indirectly caused by an activity or is accumulated over the life stages of a product.” Although there’s no one consensus definition—sometimes all greenhouse gasses (not just CO2) are included, for instance—a keyword here is measure. Again, complexities abound around that measuring—and the origins of such a project and the implications for businesses and consumers are controversial topics—but a carbon footprint mathematically represents an attempt to quantify emissions that contribute to climate change.

In the climbing holds sector, one of the ways companies have been looking to reduce the size of their carbon footprint is by using less plastic. Holds and volumes made out of wood, a renewable resource, have been around for decades—dozens of brands in CBJ’s Climbing Holds, Macros and Volumes directory practice the art of both plastic and wood grips creation. But plastic holds have unique qualities that have kept them in higher demand than wood holds at climbing walls around the world.

So, how does a plastic hold maker use less plastic? It’s a question that has been on the minds of hold brands for decades, and one that has led to numerous innovations over the years. Creating holds with hollow backs, for example, emerged in the 1990s and has been perfected over the years to the point where hollow-back holds are now more norm than anomaly. Incorporating new hold production technologies (such as 3D hold printing), designing holds that can be casted with less plastic, and experimenting with different composite materials have all been ways that brands have cut down on their plastic use.

Of late, France-based Ino’Holds has developed an eco-friendlier plastic mix called GreenMix. Instead of using 100% PE or PU, Greenmix comprises at least 25% natural hemp fibers and 11% recycled polyethylene (PET) often derived from plastic bottles. Climbing holds made with this “hybrid” mix are reportedly 40% lighter and 23% stronger than PE holds. Robin Balducci, the founder of Ino’Holds, describes holds made of this “hybrid” mix as a great alternative to PE holds and a complement to PU holds.

“We started the R&D in 2021, working with gyms, setters, shapers and climbers to find a good balance between their climbing expectations and our technology,” Balducci tells CBJ. “Using the technical properties of hemp fibers to reinforce a recycled PET resin seemed obvious to us, especially since France is one of the leading hemp producers in the world!” [A brief YouTube video of the GreenMix process can be found here.]

In Germany, allHOLDS has also been getting creative with plastic. Run by Ebalta—its umbrella company, which produces polyurethane, epoxy resin and semi-finished products in much larger industries, such as the automobile industry—allHOLDS is neither a climbing hold brand nor a manufacturer. Today, it’s well-known that the vast majority of climbing holds are manufactured by Aragon (in North America) and Composite-X (in Europe), which offer considerable economies of scale. But not all climbing hold brands take this route. The aforementioned allHOLDS is a network of a half dozen independent brands that, like Ino’Holds, manufacture many of their own holds, often using Ebalta’s unique PU plastic.

All PU plastics are the end product of a chemical reaction involving a catalyst, an isocyanate and a polyol, and there’s more freedom here when it comes to choosing the polyol side of the equation. Instead of using non-renewable polyols, Ebalta is developing a variation which is based on natural oils, such as castor oil, sunflower oil, sugar, linseed, etc. The end result will be a climbing hold composed of 40% renewable raw materials.

Ebalta helps allHOLDS network brands to reduce the carbon footprint of their production processes in a number of other ways, with the ultimate goal being that every climbing hold produced within the network would be carbon neutral. According to UN Climate Change, “climate neutrality refers to the idea of achieving net zero greenhouse gas emissions by balancing those emissions so they are equal (or less than) the emissions that get removed through the planet’s natural absorption.” Although some very large companies have used the concept of carbon neutrality to justify ongoing pollution by “balancing” the equation with carbon offsetting projects, for Ebalta engineer Clemens Saalbach the company’s carbon footprint calculation is more about staying accountable to its sustainability goals.

“Our first goal was to offer a high-quality system to every brand that wants to produce independently. But at the end of 2019, after our first meetings with our partners, we decided that we needed more than just a good system; we needed a sustainable system,” says Saalbach. “Right after we started, COVID hit the world, but everyone used this time to focus on research and development. Ebalta started to calculate carbon footprint, and we are carbon neutral since 2020. As quite a large producer of plastic products, part of our mission is to reduce our carbon footprint as much as possible.”

One of the climbing hold brands within the allHOLDS network is their German neighbor, Blocz. Saalbach says Ebalta worked with Blocz to help “eliminate the hand lamination of fiberglass and polyester,” and now Blocz is using its own patented production method.

Refurbishing Used Grips

According to the Blocz website, instead of fiberglass, the body of Blocz macros “is made out of 100% recycled industrial waste and is completely reusable.” Once the texture coating on the body of a Blocz macro reaches the end of its life, it’s possible to use Blocz’s DIY Upcycling Kit to repaint the macro and apply a fresh patch of friction, and the same goes for Blocz holds and volumes. According to Blocz CEO Tom Petzold, the DIY Upcycling Kit can also be used to recoat and retexture grips of other industry brands, as well.

While the concept of upcycling is typically understood as creative reuse which increases the value of a product, the essence here is the same: helping gyms and setters extend the life of used, expensive grips through a process that can be done right at home (although it should be noted that some required tools, such as compressed air and a sandblasting gun, are not included in the kit).

“Our DIY Upcycling Kit can be used to lengthen the life of all kinds of holds, macros and volumes, because it’s more sustainable to use the material longer instead of recycling,” says Petzold.

For folks who aren’t interested in a DIY process, there are refurbishing services out there. In Canada, Quebec-based DÉLIRE Climbing Walls, for example, has also been thinking outside the box to extend the life of climbing grips—large ones in particular. Regardless of the grips’ brand, once used macros and volumes reach DÉLIRE’s headquarters near Quebec City, the DÉLIRE team can fix structural integrity issues, reapply new texture, and replace t-nuts. As with Blocz’s system, the whole process is often much cheaper than buying the same grips anew. However, given the costs and environmental impact of shipping volumes back and forth, for the moment the service has largely been limited to gyms in DÉLIRE’s region and gyms near the climbing wall projects where their team will already be onsite.

“We won’t create a more sustainable industry if we still do things the same way all the time,” says Jeff Beaulieu, co-owner and co-operator of DÉLIRE. “So, we get to the core of our process, see what we can make better, and move on from there.”

In Europe, UK-based Contact Holds offers a refurbishing service as well that encompasses smaller climbing holds. Climbing gyms can ship old, worn out, chipped, polished or faded holds, macros and volumes to Contact Refurbished, which can retexture and change the color of the grips, repair worn out attachment points, install washers on flanged macros, and fix any chips or cosmetic damage. Contact Holds even has a calculator on their website to help estimate the cost of a repair, so gyms can weigh the financial benefit of the service against the expected cost beforehand (and know when the size of a grip extends beyond Contact’s standard pricing and requires a bespoke quote).

And in France, NRHolds, run by Nicolas Rouch, provides a refurbishing service focused on retexturing used grips of all varieties (PU, PE, fiberglass, wood). According to information on the company’s website, clients can ship used grips to NRHolds, which will then send back a quote before retexturing the grips, and NRHolds—whose clients are predominately based in France—has been covering the cost of the return shipping when the retextured grips weigh over 30 kilograms. NRHolds has reconditioned over 900 kilograms of used grips to date and, per Rouch, the company is getting into the business of recycled grips, as well.

Recyclable Holds & Macros

Among all the problems that recent sustainability efforts have been trying to solve, there’s one question that looms large: What can be done with all the old plastic holds at gyms, rec centers, universities, parks, outdoor walls and homewalls that are beyond repair and can no longer be safely used? The reality is that the vast majority of the millions of climbing grips in circulation do not make financial sense to repair and currently can’t be recycled. A next project for Ebalta has been developing a system where any old holds—just like old batteries and printer cartridges—could one day be collected, ground down, and reused for insulation panels or other products. Even more common of late, though, are businesses starting fresh and working to create climbing holds that can be recycled into new climbing holds, going forward at least.

Experiments to produce recyclable climbing holds, it should be noted, have been around for years. Finland-based Greengrip Oy, for instance, started making climbing holds over 15 years ago and, according to the company’s website, today “all [their] climbing holds are unique and 100% recyclable.”

“I started manufacturing climbing holds in 2006 with the idea of eliminating toxic polystyrene and polyurethane used in commercially available climbing holds,” says Admir Hadzic, Greengrip’s founder and CEO. “Over the years, I have tried to introduce bio-based materials into different types of climbing hold mixtures. Ideas about recyclable climbing holds, more environmentally friendly materials for climbing holds, as well as safer holds for me started more than 20 years ago. We never had any massive manufacturing, but small handmade unique product lines.”

More recently, Greenholds has put their own recyclable holds on the market. Based in the Netherlands, Greenholds has been deploying an injection molding production process instead of the standard method of pouring by hand. A typically more expensive process that’s more often used for high-volume production, injection molding involves pressurizing various materials—in Greenholds’ case, small grains of polyamide thermoplastic material that comes from waste streams in the industry—at such a high level that they turn into a molten state and can then be mechanically forced, or injected, into steel molds where the material cools and hardens to the shape of the mold. In being composed of a thermoplastic material rather than a thermoset material, like PE and PU—which form chemical bonds when curing that reportedly make them currently impossible to remold—a climbing hold produced in this way can be turned back into a molten state at the end of its life cycle and remolded into a new hold, which is exactly what the Greenholds team has in mind.

“We make holds from waste and we can 100% recycle them again. The idea is to start with a semi-circular business model and give customers a 40% discount with the next order when they return the holds,” says Tim Mullens, who co-founded Greenholds with Geert Voncken in 2019.

Not all thermoplastic grips, it should be said, are easily recyclable. The previously mentioned Blocz macros, for instance, are also comprised of a recycled thermoplastic material that goes through Blocz’s production process. Material residues generated during the production process can be returned to the recycling loop, but when it comes to the grips themselves, “at the moment it’s not possible to return the thermoplastic material from Blocz-produced macros due to the very durable and well-adherent coating,” says Petzold, noting they are “working on this problem to be solved.”

While Greenholds’ grips are recyclable, currently the hold lines are visibly not quite as diverse or creative as other modern lines on the market. One of the difficulties with using injection molding for climbing hold production is getting the right shape, texture and density, and many of Greenholds’ first hold products are mostly uniform in shape and smooth in texture, making them generally more suitable for training purposes than commercial setting. But the experiment has nonetheless produced some of the world’s earliest recyclable climbing holds, and Mullens expects their recyclable holds for commercial setting—including a down climb jug—to hit the market by the end of the summer.

“We don’t say our holds are perfect or the best out there,” Mullens added. “We think we have made a first big step toward a solution to make our sport more sustainable.”

Recyclable climbing holds being sold by only one brand, though, has limited impact on the recyclability problem if the rest of the new grips hitting the market each month are not recyclable. Mullens noted they have since pivoted their strategy to include manufacturing recyclable holds for other brands, and they won’t be the sole company doing so.

Ghold, based in France, has had the mission of being a recyclable holds manufacturer for the industry practically from the get-go. Ghold also uses the injection molding production process described above, but with two key differences.

Founded by climbers and materials experts Benoit Jacquot-Bertrand, Sébastien Leprivey and Hugo Pheuplin, Ghold has developed its own thermoplastic, patented material that went through multiple iterations during the R&D stage to get to where it is today. In brief, Ghold buys thermoplastics—either virgin material or plastic waste from other industries (30% from recycled origins at the moment)—and turns them into Ghold’s small thermoplastic grains which then go through the injection molding production process to become new climbing holds. Thus far, the experiment has yielded new holds that look nearly identical to PE or PU versions of the same shape.

The other secret lies in the molds Ghold uses. Per Jacquot-Bertrand, since injection molding involves very high pressure, steel molds are most often used, but one steel mold can cost thousands (if not tens of thousands) of dollars. Businesses in the plastics industry recuperate those costs through economies of scale (think 100,000 Lego pieces), but in the climbing hold sector one hold may only be produced 300 to 500 times. To make the process profitable, Ghold also developed their own molds that are far cheaper—reportedly 1000 times less expensive—than normal for injection molding.

“We have been developing a production technology that meets the demands around price, scale and texture in the climbing holds sector,” says Jacquot-Bertrand. “We have developed our own molds that are more affordable and complex, so that the process is more economical and the climbing holds are even more precise. Thanks to our innovations, we can produce climbing holds that have a dry grip and are practically identical copies in terms of shape, at a price that’s comparable to other hold manufacturers.”

Although Ghold is still getting its factory up and running since developing their thermoplastic material and molds, the idea is that new grips produced by Ghold for hold brands in the industry could be sold or rented to climbing gyms around the world which could later return the holds, at the end of their life, back to Ghold to be broken down, altered and remolded through the same production process at least ten times, according to Jacquot-Bertrand.

Ghold has started out by focusing on smaller holds (XS to XL sizes), both to keep a tight scope and because smaller holds are rarely worth the cost of repair. But Ghold and Greenholds aren’t the only businesses experimenting with recyclable climbing holds. A third climbing hold company, in Canada, has taken the plunge, shifting the production of all its holds and macros—big and small—to an entirely different process.

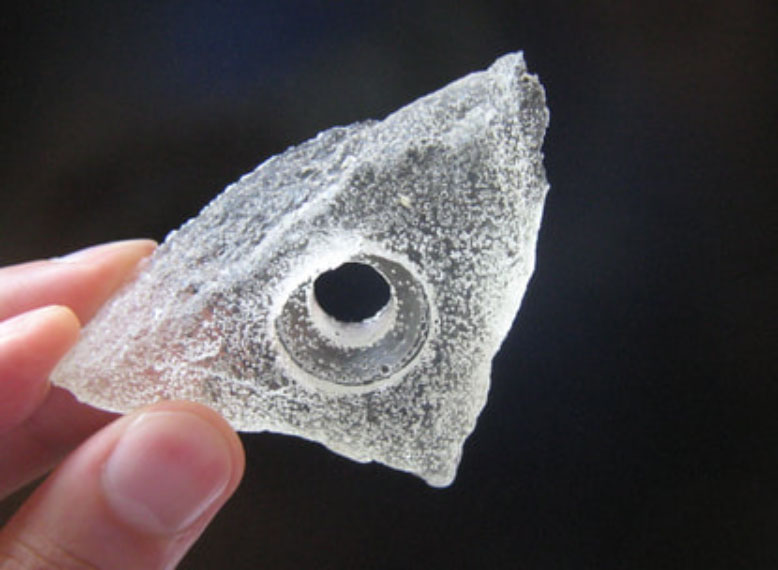

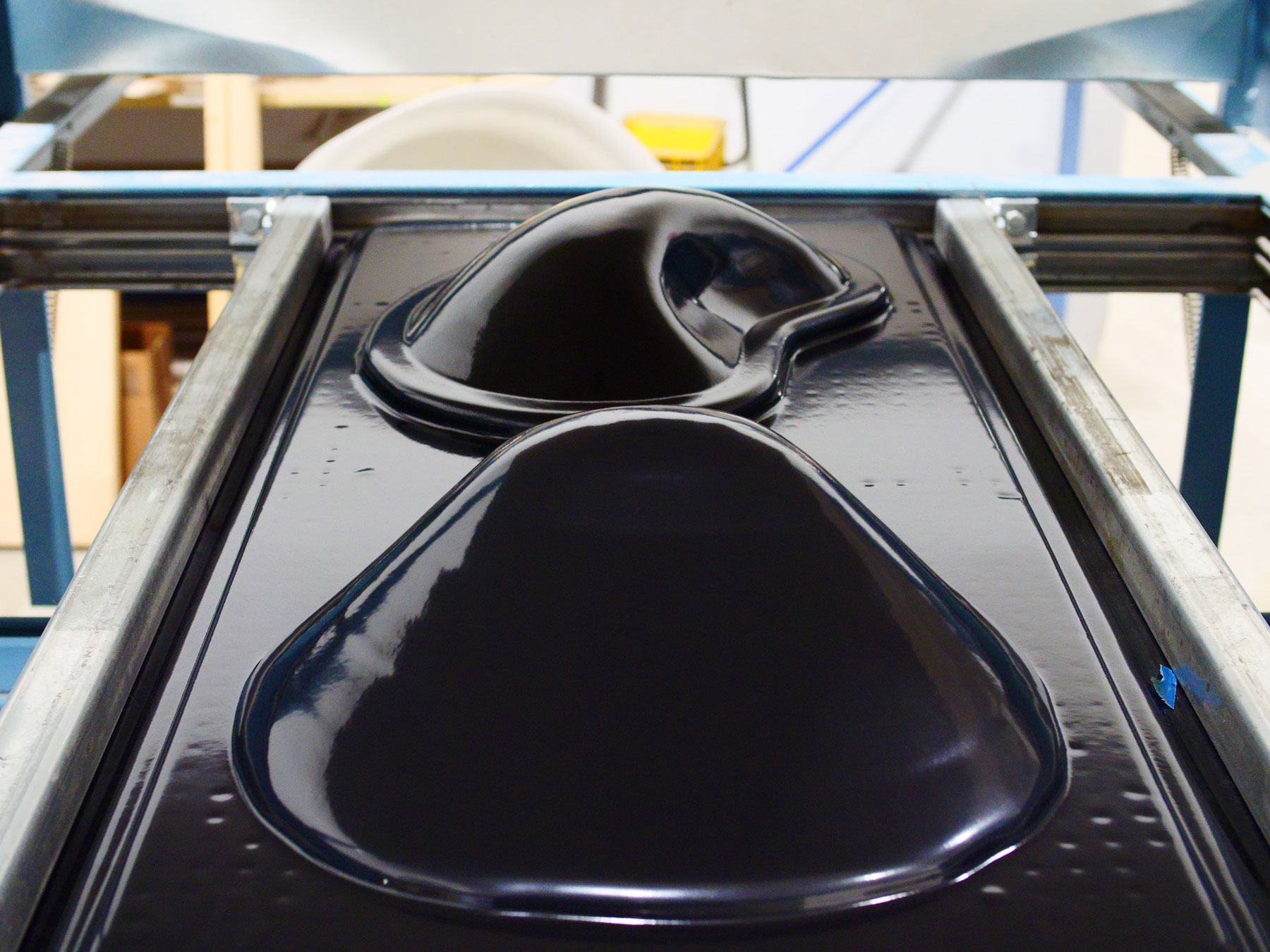

Binary Holds, a Calgary-based brand, is now using vacuum thermoforming (VTF) technology to manufacture its climbing grips. VTF entails taking a sheet of thermoplastic material—in Binary’s case, acrylonitrile butadiene styrene (ABS)—heating this sheet in an oven until it can be deformed, setting the heated sheet on a mold, vacuuming air out of the mold to pull the sheet tight against the mold to shape it, and then letting the formed plastic cool and harden before it’s removed from the mold. According to Scott Eveleigh at Binary, their ABS holds produced using this process more closely resemble fiberglass macros on the market today, are far lighter than PE and even PU holds, and are 100% recyclable. (Binary has a process for removing the texture coating before recycling the ABS plastic). And to cut down on waste, the VTF technology is aided by a 3D imaging process that involves “scanning existing holds or masters and scaling them to any size, reducing the need for multiple foam shaping models for different-sized holds,” adds Nevin Alexander at Binary.

“We completely stopped our PU production late last year to focus solely on VTF,” says Eveleigh. “We have had a complete overhaul of our production process since almost nothing carries over. We’ve had to start from scratch with new machinery and methods, which has involved a lot of research and development to get to where we are now.”

Despite the big shift, Binary has already started to manufacture some ABS holds for major hold brands, including Kilter, Trango, Grizzly, Capital and Stone Age, in addition to producing some ABS shapes and sets for Binary. Whereas injection molding is generally considered more cost-efficient for high-volume production, VTF is typically more cost-efficient for low-to-mid-volume production, more akin to the production levels seen in the climbing holds sector. “VTF is great for rapid prototyping…as there are a large variety of options for creating forms/molds,” Eveleigh says. “This works quite well for us, as we are able to quickly test different shapes and styles of holds, then transition into something more suitable for long-term production.” And, as Eveleigh notes, the rising cost of PU may be making these kinds of alternatives more viable.

“The climbing hold industry is on the cusp of change,” concluded Eveleigh. “The traditional materials for hold manufacturing (PU, PE and fiberglass) are petroleum based and cannot be recycled and don’t degrade easily. These holds will inevitably get thrown out after their life cycle and waste away in landfills. Recently, there has been a shift in the industry, and many climbing hold companies are exploring alternative materials and methods for production in a more environmentally responsible way. Whether it’s recycled/recyclable materials, upcycling programs, or bio-based materials, it all makes a difference. It’s really exciting to see, and we are excited to be a part of it all. We see gyms in the future committing to more sustainable climbing hold models as hold technology develops and new innovations are found.”

John Burgman is the author of High Drama, a book that chronicles the history of American competition climbing. He is a Fulbright journalism grant recipient and a former magazine editor. He holds a master’s degree from New York University and bachelor’s degree from Miami University. In addition to writing, he coaches a youth bouldering team. Follow him on Twitter @John_Burgman and Instagram @jbclimbs. Read our interview Meet John Burgman, U.S. Comp Climbing’s Top Journalist.

Joe Robinson has been working in the climbing industry for over a decade and currently manages CBJ advertising and editorial. He traveled the world as the IFSC’s community manager during Olympic inclusion and across the US while writing for Alpinist, Climberism, DPM and CBJ. He also worked in local climbing gyms of the Pacific Northwest and West Michigan while advancing economic empowerment, educational equity, youth development and diversity programs of national non-profit organizations.

Joe Robinson has been working in the climbing industry for over a decade and currently manages CBJ advertising and editorial. He traveled the world as the IFSC’s community manager during Olympic inclusion and across the US while writing for Alpinist, Climberism, DPM and CBJ. He also worked in local climbing gyms of the Pacific Northwest and West Michigan while advancing economic empowerment, educational equity, youth development and diversity programs of national non-profit organizations.