Frequently Asked Questions about Climbing Walls

How much does a custom climbing wall cost?

Climbing walls built by a professional wall manufacturer average between $25 to $45 per square foot. The price depends on many factors including the size of wall, wall type, design (including the height and complexity of design), and the construction of your building, which impacts how the wall will be attached and supported.

How are climbing walls constructed?

Most climbing walls start with a custom steel (sometimes wood) superstructure to support the climbing walls. The structure is then covered with panels that become the climbing surface; these panels come in a variety of materials, colors and finishes. Each panel has a grid of t-nuts (threaded nuts) that allow you to bolt modular climbing holds to the wall.

Are there design standards for climbing walls?

Yes, the Climbing Wall Association has published Design and Engineering Specifications for indoor climbing walls in America.

There are also standards from the European Committee for Standardization: Artificial climbing structures – Part 1: Safety requirements and test methods for climbing walls with protection points (EN 12572-1:2007) and Artificial climbing structures – Part 2: Safety requirements and test methods for bouldering walls (EN 12572-2:2008)

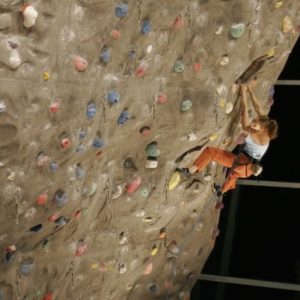

What types of climbing walls are available?

While there are many different materials and designs available, most fall into four main types: Panelized, Seamless, Rock Realistic and Modular.

| Panelized | Wall sections are built and pre-finished at the factory with textured paint or epoxy and assembled on-site. |   |

| Seamless | Walls are built on-site, then coated with a cementitious, epoxy or paint texture to create a uniform wall surface. |   |

| Rock Realistic | Custom made fiberglass or glass-fiber-reinforced-concrete (GFRC) panels are built at the factory, assembled on-site, and then coated with a concrete and fiberglass mixture to create a uniform rock façade. |   |

| Modular | Standardized fiberglass, glass-fiber-reinforced-concrete (GFRC) or wood panels are pre-manufactured and assembled on-site in a modular fashion. |   |

| Wall Type | Pros | Cons |

| Panelized | Shorter install time Lots of design options High degree of routesetting flexibility Easier to remodel |

Texture wears off over time Panels show more wear (scuffs and rubber streaks) |

| Seamless | Historically, the industry standard Very durable Low maintenance Lots of design options Moderate degree of routesetting flexibility |

Longer install time Difficult to remodel Coating prone to cracking |

| Rock Realistic | Very durable Can be installed outdoors Aesthetically impressive |

Most expensive Longest install time Low degree of routesetting flexibility Heavy: requires adequate load-bearing structure Difficult to remodel |

| Modular | Least expensive Can be installed outdoors Shortest install time |

Limited design options Low degree of routesetting flexibility Best for non-climber markets (rec centers, schools) |